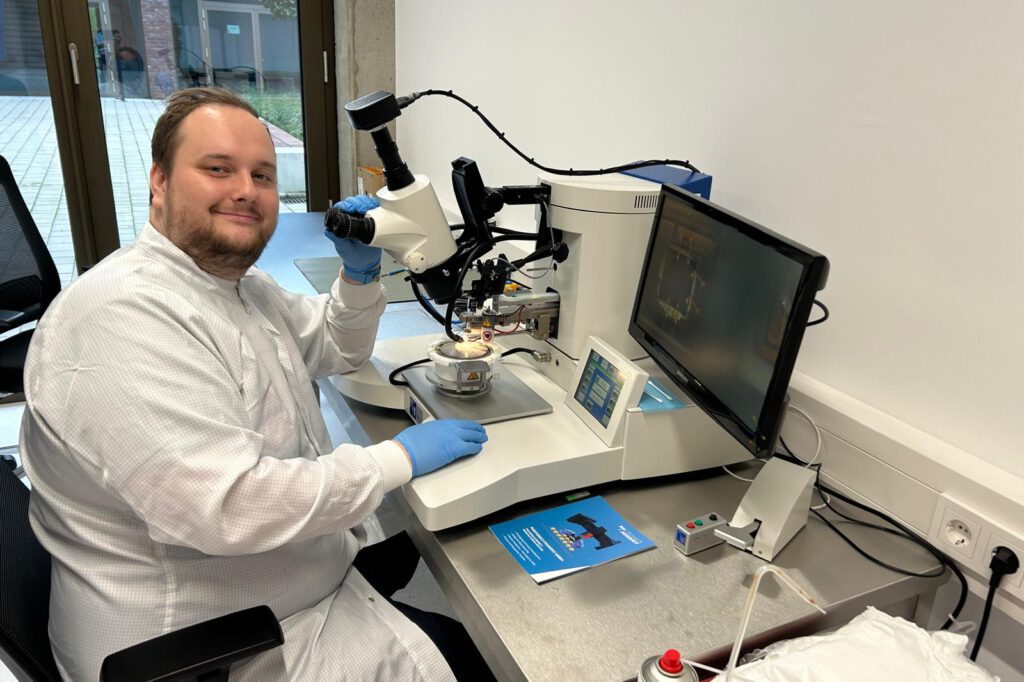

The Photonics Foundry was created because we felt that there was obviously a great need for consulting, prototyping and assembly services in the field of MEMS and photonics.

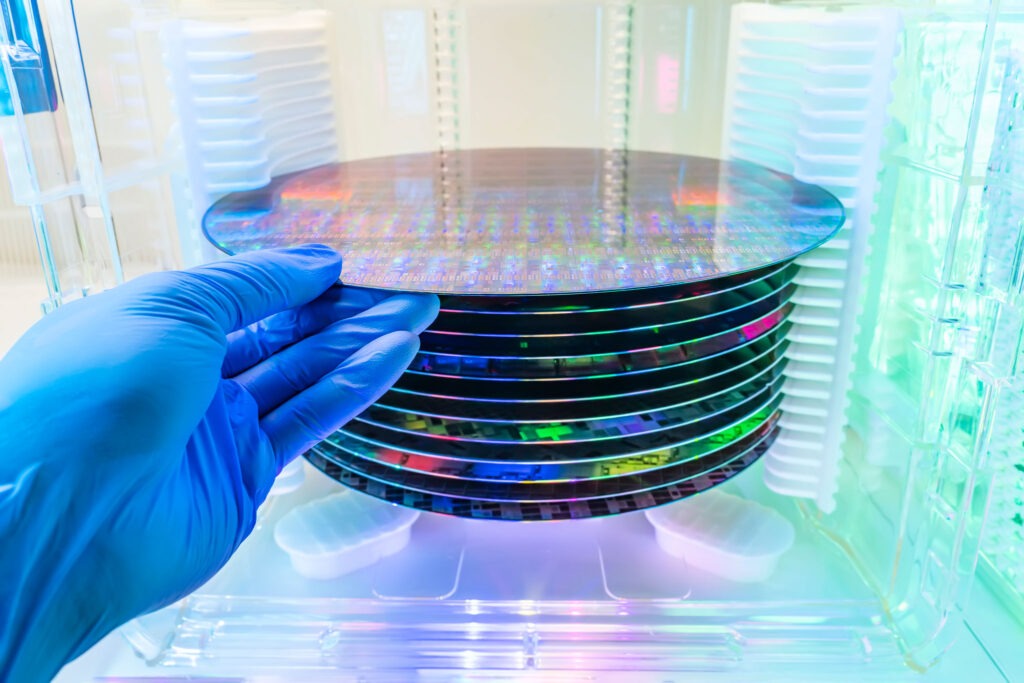

In a market with an expected CAGR of over 20% (see various reports and market analyses), there is currently a strong spirit of optimism. In such a buoyant environment – with many up-and-coming companies in areas such as LiDAR, RGB projectors, augmented reality, health monitoring, telecommunication with lightspeed, interferometers and many more – it is not surprising that there is a certain amount of uncertainty as to how the manufacturing demands of the rapidly growing market can be met. After all, very few photonic devices are currently suitable for standardized mass production. Additionally, not every company wants to, or even can invest in expensive precision alignment machinery, cleanrooms and qualified employees –this is where Photonics Foundry comes in, this is exactly our field.

The three partners have over 50 years of combined experience and have realized countless high-tech projects. They have supported and advised customers at various stages of product development. New technologies for active alignment and the combination of different materials, e.g. with eutectic systems, epoxy-based adhesives, laser welding and cross-platform production options have emerged from this expertise. And always with the aim of creating an added value for our customers at every stage.

Global political developments are showing more and more just how important local and reliable supply chains are within a friendly environment. The vast majority of semiconductor, microsystems technology and photonics suppliers today are dependent on sending wafers and materials around the globe several times, in order to be able to complete all production steps. This not only causes long production cycles, it highlights a rather carefree use of resources and an unnecessarily large CO2 footprint.

This is why Photonics Foundry, wherever possible, will rely on local suppliers and deep vertically integrated production pathways – not only to be able to act quickly, but also to be able to act responsibly.

The right time for the Photonics Foundry is right now.